Description

BERNHARDT’s TTAB bag in boxes (Tuck Top Auto Bottom) come in four sizes: 20, 40, 60 and 80 litres. Moreover, the system formed by the box and bag is suitable for the transport of dangerous materials. Indeed, it is UNO/UN approved for volumes of 40 L and over.

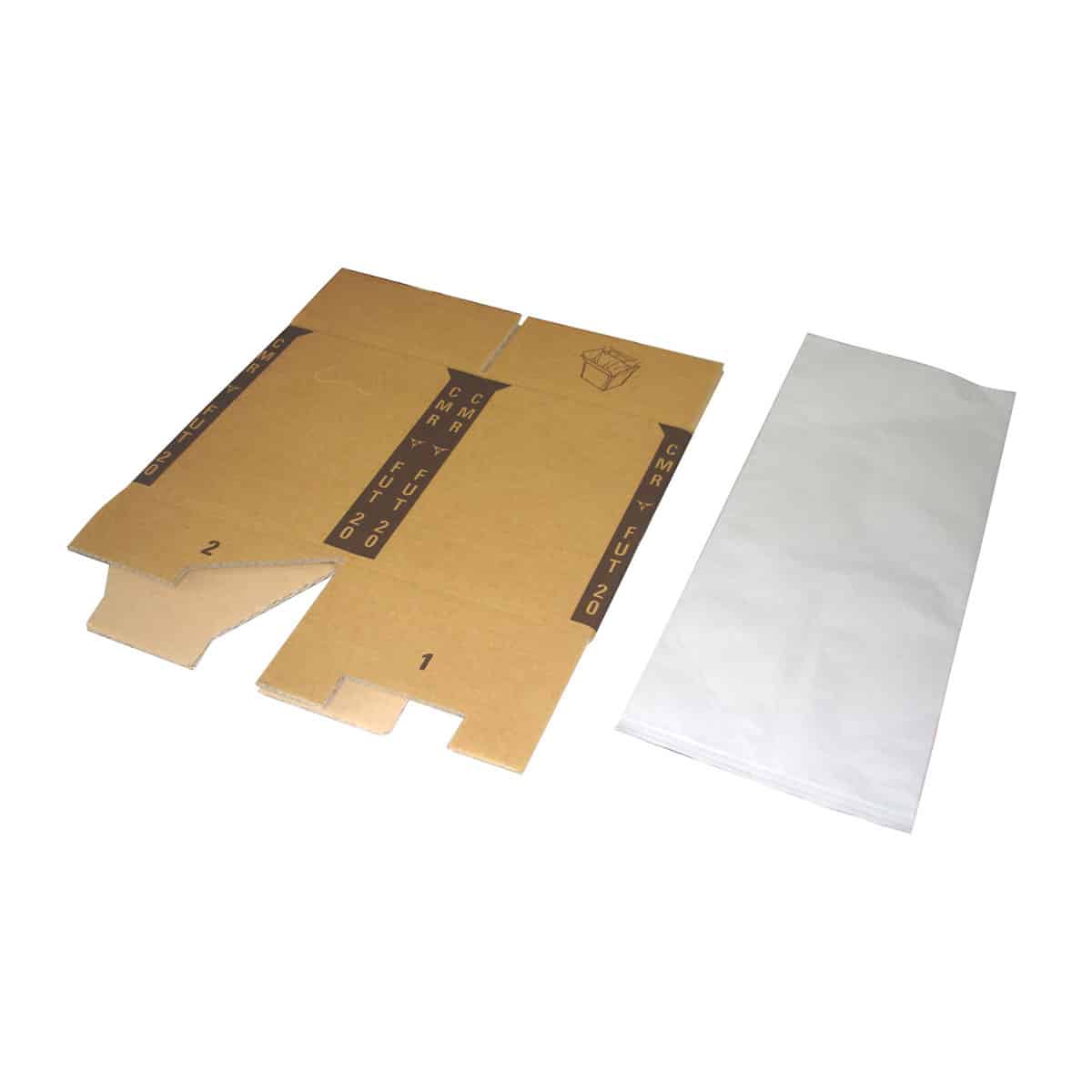

Additionally, the boxes and liners are delivered flat. Minimum order quantity is 50 units for 60 and 80 L bag-in-boxes. It is 100 units for the 40 L model and 160 units for the 20 L models.

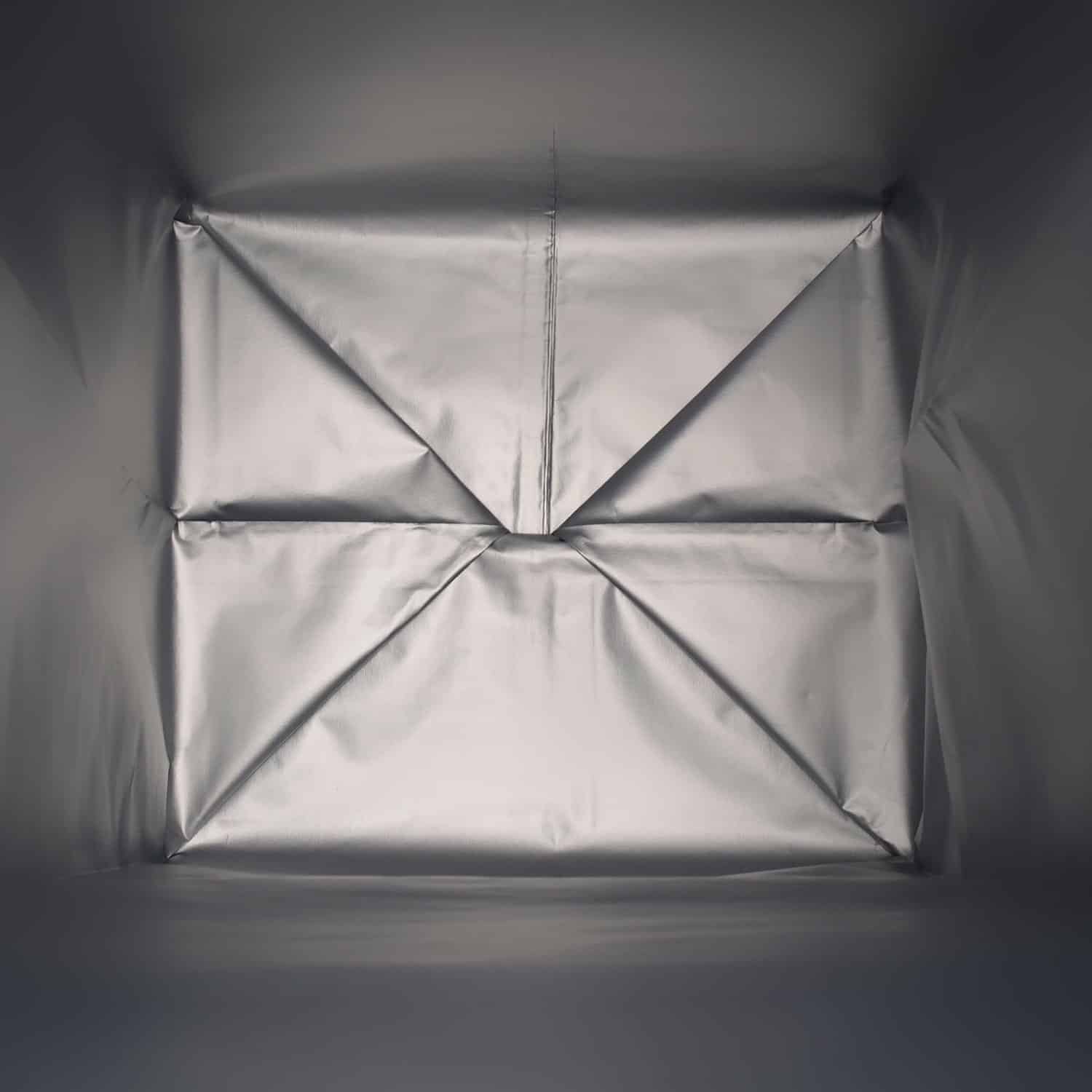

The bags are manufactured by BERNHARDT using a paper-aluminium-PE triplex high barrier film. Furthermore, that high barrier film is compatible with the vacuum packing process.